This lyocell article is my first follow up to a previous article on viscose, for which I had a number of comments questioning sustainable alternatives, bamboo (I will talk about this another day!) and ethical fabrics in general.

Fibres within the regenerated cellulose family

Viscose, lyocell, modal, cupro (which you might know as Bemberg), acetate – as a seamstress these will probably all sound familiar to you. What they have in common is that they are all cellulosic fibres. They started life as plants, were turned into pulp, had chemicals added to dissolve the pulp, and went through a spinning process to turn them back into a fibre that could then turn into a yarn. What makes these fabrics different from each other are factors like the feedstock used (for example, cupro uses cotton linter instead of trees) or the chemicals needed to dissolve the pulp.

There is a bit to say about each of the fibres so I am going to split the blog posts up about these. This one is about lyocell, which is often heralded as the one with the eco friendly credentials. You might know it as Tencel™, the trademarked name for the lyocell produced by Austrian manufacturer Lenzing.

Lyocell: a regenerated cellul]ose fibre obtained by dissolution, and an organic solvent (mixture of organic chemicals and water) spinning process, without formation of derivatives – as defined by EU legislation.

(Note that the US the Federal Trade Commission (FTC) also has its own definition as a subcategory of rayon which is along similar lines).

What makes lyocell sustainable?

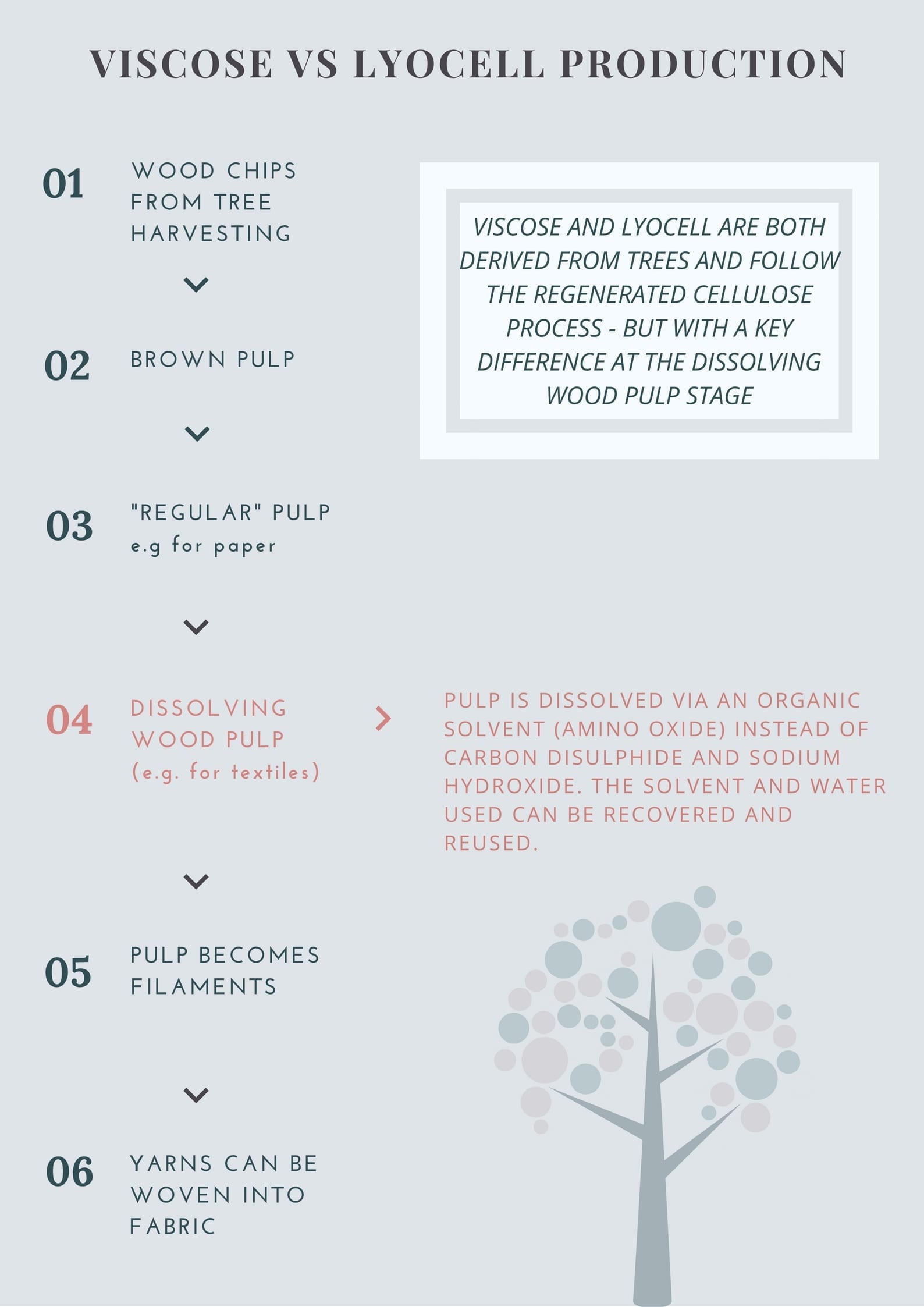

The production process is largely the same as viscose, but with a key difference as you can see in my infographic below. (the viscose infographic which includes descriptions of each step is in this post here.)

Viscose vs lyocell production

The primary benefit is the dissolving wood pulp step, where the chemicals used are different from viscose. According to Lenzing , probably the most famous of lyocell producers, the sustainability factor comes from the closed loop process. The solvent (amine oxide solution) that dissolves the wood pulp is non-toxic, and 99.5% of the solvent and water in the process can be recovered, recycled and reused.

Where have I seen lyocell (or Tencel™) before?

Lyocell has been been around for a long time; the name was recognised in the US with the FTC back in 1996. I know I have crossed paths with it – I can recall owning a pair of red Tencel™ jeans in the 90s! (no kidding! I was Miss anti fashion). The sticking point for me back then was because they were so different from my regular denim jeans, a bit floppier and had a smoother texture. As time went on and the red jeans wore out I kept a lookout for more Tencel™ clothing but without much success. It seems 20 years later it still hasn’t completely made it into the mainstream. Especially when you consider that the whole regenerated cellulose family is less than 10% of global fibre production.

Why is lyocell being marketed as the new great thing now?

It does amuse me in some way that this can be the case, seeing as the technology is not new. Most recently I have seen the brand Citizen Mark marketing a new Kickstarter campaign for a new range of lyocell shirts. Their marketing line is Better than Silk– machine washable, sustainable, breathable. To be fair, other more well established brands have been selling Tencel™ clothing for awhile. I do find it a little curious as to why lyocell was never a super cool kid back in the 1990s. Here are some of my ideas:

- The need for it wasn’t as urgent in the 1990’s; we had cotton and polyester and were happy with that. In this day and age of climate change, sustainable fashion is becoming in vogue (and I hope its here to stay). Consumers are more demanding in this area and retailers need to do more to look responsible.

- Consumers get used to what is available to them. In a previous post I discussed the book “Curing affluenza” which discussed different solutions for changing culture and what is available in the market. It is unlikely that we will see lyocell as a mainstream product in fabric shops if we don’t ask for it. But fabric shops generally stock from textile manufacturers or from overstock (leftovers from industry, e.g. excess from factories) – so the textile industry also needs to be scaling up the use of this fibre. And so on and so forth.

- The feel of 100% lyocell is quite different from viscose. They both have the same drape and a sheen that reminds me a little of silk. But texture wise when you stroke it, there is a resistance (kind of like soft baby skin or suedette) rather than being smooth liquid silk. Eileen Fisher state on their website that Tencel has a cottony feel and that viscose is still more versatile.

- Production cost is likely higher than viscose. Lyocell was invented in the 1980’s whereas viscose has been around for about 200 years. It costs money to upgrade technologies, and if the product ain’t broke and consumers still love and demand it, I would suggest there is little incentive to change.

PeopleTree Tencel™ blend tee and Eileen Fisher Tencel™ trousers

How much more sustainable is lyocell than viscose?

Beyond saying lyocell is more eco friendly, how much is difficult to quantify. There are different ways of rating fibres depending on the mix of weightings and factors, for example, water usage, carbon impact. The Made-by consultancy rating (used by brands such as H&M) gave lyocell a B vs viscose an E (ratings go from A to E). However, this rating is 5 years old and due to be updated in 2018. The Higg Material Sustainability Index is another system used by big fashion brands (e.g. North Face) which assigns a single aggregate score based on different criteria. The lower the better. The score for lyocell as 48 (Amber on their traffic light scale) and viscose as 53 (just tipping into red) – suggesting that lyocell really is only marginally better (as an aside, alpaca is 281 which is off the charts red).

My conclusion here is that the emphasis of lyocell’s sustainability being focussed solely on production implies that the benefits are isolated. For example, the colouring and finishing of lyocell is likely the same as other fabrics.

If lyocell is fairly uncommon fabric where can I find it?

I decided awhile ago that if I was going to look at buying viscose anyway (because of the drape), it would be worth looking for a lyocell alternative if I wasn’t going for silk.

UPDATE MAY 2020: For the everyday dressmaker, there are various shops which stock Tencel™ under the Meet Milk and Mind the Maker fabric brand. If you are looking for something wholesale or thinking about suitability for your own brand, you really need to be doing your own homework. Or pay a fashion sourcing consultant to help you which is what I did. Specialist knowledge is not free and there’s a good reason for that. (Can you tell I’ve been asked about this one too many times? 😉 Rant over.)

22 comments

I love tencel! I buy it often from blackbirdfabrics (she’s only across the strait from me 🙂 ) I’m not so crazy about viscose to be honest. If I’m going to go to the trouble to sew such a wiggly fabric I’m in for silk 🙂

I agree, it is a lot of trouble! At this moment I have no Tencel, but like viscose I would imagine it can go in the washing machine and survive better than silk? Or do you have other advice for me Kathleen?

Really interesting! Thank you.

You are very welcome, thanks for reading ????and if you do have any topic requests let me know!

IKEA has lyocell bedding and duvet covers, at least in the Netherlands. Maybe they have the fabric too for home sewing.

Thanks Sandra, I’ve not seen dressmaking fabric in IKEA but I have seen stuff for furnishings. I’m going to check out their bedding here – might be a print or something that looks nice for future reference! Thanks for the idea

Thanks for the info! I hope the resources that CAN be reused in producing Lyocell ARE being reused! I’ll definitely look out for them in Spotlight.

No worries Sil, I was surprised when I saw a blogger had made a dress out of Tencel found in Spotlight! Not sure if it was a one off but if it is permanently available that is a good thing!

Thanks for the link to the Higg MSI, which I haven’t heard of before. I’m still assuming (because there is some evidence, although Lenzing says it’s unreliable) that all rayon-type fibres (including Tencel and ‘bamboo’) shed plastic-like microfibres when washed. For me, that rules them out until there’s clear evidence to the contrary. The intense processing also means I would only ever see them as luxury fabrics, not everyday ones.

OK, have just had a look at the Higg MSI – I have my doubts about any system that rates polypropylene (petroleum-derived, not at all biodegradable) as the most sustainable fibre!! I notice they say all their data comes from the industry, rather than independent research…

Hi Nina. As I understand from my sustainable fashion friends and the UAL course I did there is currently no one way to assess a fibre – various methods use different criteria. This is just one. If you have another then please do share with me! The cynic in me says that some of the big brands have good sustainability type credentials because they are probably the ones who have the money to spend on this stuff, and you also need them to be on board to effect change…. at the end of the day there is no perfect answer. For me personally it’s using less, buying less and if I can make a change in my choices that is a bonus – but at the same time just me has little to no effect.

Extremely informative! Thanks!

I bought a Liz Claiborne Tercel top that lasted for 10 years, washing in the wash machine and line drying. The fabric stayed the same for a really long time- so it may be sustainable because of long wearability. I have never had viscose clothing last that long, even with hand washing.

Hi Janie, I think any long wearing piece of clothing is going to be more sustainable than buying something new, or being made with virgin fabric. I haven’t seen a lot of 100% Tencel around in fabric stores, and what I have seen in RTW tends to be blends… but having said that I haven’t truly shopped RTW for a long while! Good to know that you had a good experience with it.

While I understand the ease of relying on scores as sustainability metrics, I really think we need to add more context and complexity to sustainable fabric considerations. Two things I’ve read about lyocell are that it is a closed-loop chemical process, meaning the effluent is recaptured as opposed to the waste and waterway issues associated with rayon broadly, and when lyocell is Tencel (trademarked by Lenzing), the wood is sourced from traceable and certified sustainable sources, whereas rayon forestry practices are opaque and abysmal at best. Even if that is only a “marginal” increase of points on a rating system, I think in a broader systems context they represent critically important steps worth supporting if one is in need of fabric with rayon-like characteristics. This is one issue I see with relying on ratings systems, which as you note above look at varying arrays of data related to fiber and fabric production, but still lack a certain holism — Higg, for instance, is a “cradle to gate” metric which means that it’s not taking into account end of life care, microplastics pollution, etc. And it’s clear that Higg, like many metrics, skews toward man-made fabrics because all agricultural land-use impacts are viewed as negative — that’s why the alpaca fabric rates so “high” (i.e. bad) – because, in its own description on the Higg MSI site, the alpaca LCA is based on Peruvian production where the alpaca are dispersed among hillsides, therefore a larger landscape base = “worse impact.” Can agricultural practices and animal impact be improved? Absolutely. But as it stands, the rankings are basically saying that animal manure and methane on pasture (as opposed to confinement), is more harmful to people and planet — by many orders of magnitude — than extracting earth minerals, melting them at incredible temperatures to make glass (with noxious air impacts) and making it into fabric (glass fiber is the #1 lowest rated textile in Higg’s MSI). I know this is a tangent quite far from the lyocell conversation, and I deeply appreciate your thoughtfulness and conversation facilitation around sustainable sewing, so I just wanted to try to draw out some bigger framing ideas. Lastly, with regard to Higg and other metrics, I’d like to pose a question for sewists: one main reason I sew, and I see others sharing this as well, is to produce my own clothing that is distinct from the fast fashion system, in pace and ethics and style — so why then would I rely on their ratings, which prioritize their perspective on materials which can support their current operating system and scale? I encourage anyone who is interested in creating their own clothing to also think creatively beyond the inherently unsustainable mass production system and the metrics that are embedded within that lens.

Hi Jess, thank you for your comment – happy to see a lot of people feeling quite passionate about this and getting the conversation going! So on closed loop; yes I have highlighted that in the post. On the sustainable forestry practices, yes I agree this is worth supporting as well but there are also problems associated with forestry (and with being alive in general!). But now you mention it the reason I left it out is because whilst this is applies to Lenzing, the strict definition of lyocell states nothing about feedstock and I understand they are not the solo producers of lyocell. Secondly (and shoot me for saying this), if we are thinking broadly about the forestry problem I am sitting on the fence about the scale of it. I wrote in my previous viscose post that Canopy Style says that >150 million trees are logged each year for textile purposes. There is no context around this number that I can find and to me that is like saying “photo or it didn’t happen”. Using a rough methodology on tree density from Rainforest Network, this number is a really small percentage when compared to timber harvesting, agriculture and wildfire spread – so I would almost be tempted to say that we have other things to worry about. But the point here is that there are a lot of frightening sounding statistics that are difficult for the average consumer to REALLY understand, you can contextualise as broadly or as narrowly as you want and be underinformed about all the interlinked complexities. We could start talking about here about livestock and a vegan lifestyle… but then we might be here all day 🙂

In terms of Higgs and other metrics – I think it is interesting to see what fashion is doing, especially while there continues to be more people buying that sewing clothes. I don’t believe we are that disconnected as fabric shops tend to follow trends, and the ones I know are stocked with deadstock or stuff from textile brands (another topic in itself!). There have been many times when I’ve seen distinctive ex high street brand fabric on sale at a fabric store. Of course this doesn’t apply to you if you are a champion thrifter and up cycler that never buys from a shop, in which case your footprint is already better than someone who buys virgin “eco” fabric. Personally I started sewing out of necessity and an abhorrence of shopping in general, but then fell into the all-the-fabric trap. Whilst I’m obviously really interested in textiles, in the absence of knowing everything about everything, my focus as a sewist is LESS. Make less, wash less, use what I have. The only more I want to do is getting better wear out of things I have.

Let me stop now and finish by saying thanks for taking the time to read and comment – love to have this kind of debate. Look forward to connecting with you more on here or IG 🙂

I have bought tencel from myfabrics.co.uk (European shop) and I’ve seen it at https://www.stonefabrics.co.uk (bricks and motor shop in Devon). Another great post thank you.

Ah I had forgotten about myfabrics.co.uk. I must admit that in my naivety when I first ordered from them that I thought they were actually in the UK! Thank you for sharing your sources

Just received my order of this today.

https://likesewamazing.com/product/medium-blue-tencel-chambray/

Not cheap but feels beautiful

Try Merchant And Mills too for Tencel in UK if you haven’t already found it.

Metermeter https://www.metermeter.dk/1/stofbrand1/meet-milk.html (in Denmark) has a big range of Tencel. A very dangerous shop! You have been warned

Hi Emma, thanks for reminding me to update the post! Metermeter own MeetMilk which in the last year seems to have a monopoly on tencel based fabric for shops catering to home dressmakers in Europe. The MeetMilk website lists at least 50 stockists I reckon, most of them in Germany.