Local or offshore production? Transparency in the fashion business is a funny beast. I love everything about apparel fabric and for the past few years I’ve always wanted to do something with fabric – but not in the traditional way. Every time I think of clothing or fabric production my autopilot mind heads offshore. Mostly Asia, but also Turkey, Poland or Portugal. The million-dollar question though: even if I know where my stuff is made, does it actually change whether I would buy it? Apparently I’m not the only one thinking about this:

“Have you become obsessed with looking at your tags to see where your stuff was made? …. why was this the case and what led the company to do their production there?”

Kestrel Jenkins, Conscious Chatter podcast

I start by thinking about my interpretation of local. For me, this is typically about smaller companies with a proportion of operations in-country. As opposed to a company that happens to be founded or headquartered here but outsources all production.

Clothing vs fabric transparency

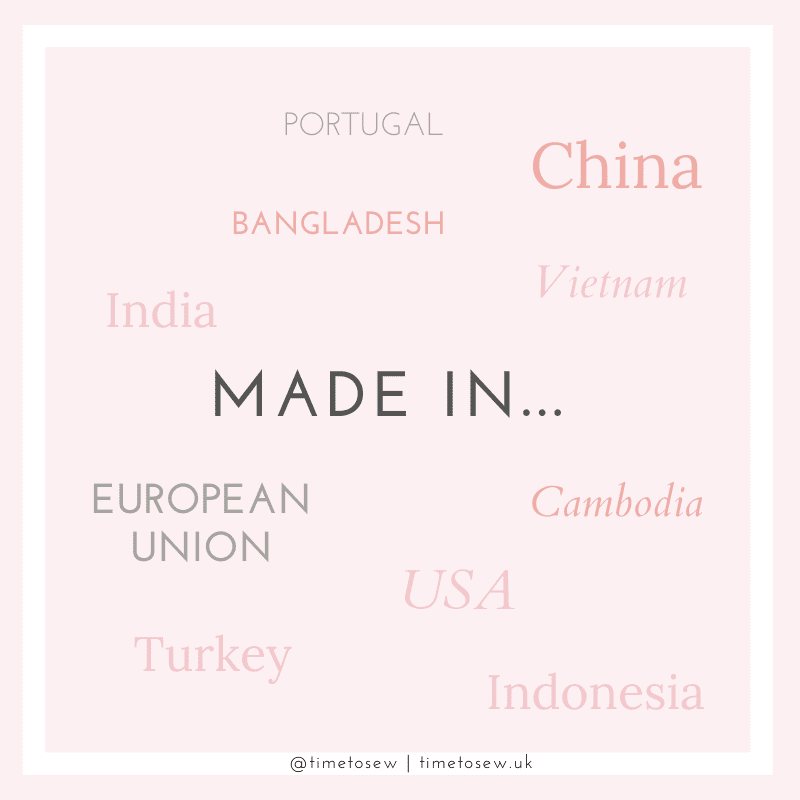

Transparency in terms of where clothing was made is a mainstay of sustainable fashion brands. The only high street name I know which makes a song and dance about transparency is H&M. Click on a product online and you’ll see the name of the factory where it was produced. Whilst it’s a positive initiative, is the average consumer going to track down the working conditions etc. of the listed factory? Do they care whether the label says Made in China or Made in Turkey? (or anywhere else?)

Finding the “where” is less easy when it comes to textiles in general (as opposed to RTW clothing). According to the World Trade Organisation (WTO), in 2018 the top textile exporting countries (all textiles not just clothing) were … *drumroll*…. China – by far the largest (no surprises there), followed by the European Union (no breakdown of specific countries). Then Bangladesh, Vietnam, India, Turkey, Hong Kong, Indonesia, Cambodia, and the USA. In terms of top imports, the EU sits at the top of the list followed by the US and China.

How did we get to this situation?

The end of the WTO Multi Fibre Arrangement in 2004 meant that quotas on clothing/textile exports from developing countries were lifted. You’ll hear it reported that this was a key reason for the death knell of manufacturing in Western Europe and the USA. Not to say that there isn’t any manufacturing left, but there is no doubt that it has dwindled due to cheap labour elsewhere. (I could write a whole essay on this but not today).

However, fast forward 15 years and the situation is changing a little. Labour is no longer as cheap in top manufacturing countries and there is even talk about whether near-shoring of apparel manufacture is going to happen. A quote from an interesting report by consulting house McKinsey & Co last year (well worth a read if you have time/interest – link below):

79% of respondents in our survey believe that a step change in nearshoring for speed is highly/somewhat likely by 2025.

McKinsey & Co, “Is apparel manufacturing coming home?” – October 2018

Why I choose local over offshore (where possible)

Given the manufacturing situation in Western Europe, finding fabric that is locally produced has for me always found a bit of a challenge. (Less so for clothing as small sustainable fashion brands do the work for you). And even if the fabric is marked Made in Italy or Made in the UK, what do you really know about it? There have been some pretty shady stories about local manufacture as well which I’ve linked below. Instead, I’ve typically gone for the deadstock / second hand / small independent fabric store route where I feel I can connect with the person running it.

When I then decided to look at fabric production and sourcing, my research told me that selling fabric is a volume game where offshore, large volumes or trading deadstock wins if you want to be really commercial about it. Doesn’t mean to buy sell fabric that way is a bad thing, just that it wasn’t going to be my thing.

Which is why I really feel strongly about being able to put out something for sewists with my recycled fabric project with Enschede Textielstad (launching next week!) The fabric will only be available as part of a kit. Here’s a sneak peek where you can see both sides of the same fabric in the teal colourway. And yes, the leather is upcycled and local as well.

Factors to consider in the local vs offshore production debate

But I digress. Continuing with the theme of things to think about with local vs offshore:

1. It is often not possible and/or financially feasible for retailers to source locally manufactured products.

There needs to be a demand for a product at a price point that people are willing to pay. The labour cost and the standards of living in Western Europe mean that products manufactured here are likely to be higher priced (unless there’s a lot of scale). The cost of wholesale then makes it hard for the retailer to make a living.

On the flip side, I don’t think I’ve ever heard any local craftsperson say that they don’t work hard for a limited amount financial return. Especially if they make things themselves and don’t outsource, then they don’t have a scalable business.

2. Local doesn’t always mean better.

True story. Heard about exploitation in the UK? The Environmental Audit Committee work into fast fashion this year heard evidence about garment workers in Leicester being paid less than UK minimum wage. And in Italy there can apparently be some pretty shady practices as well, read about that here.

3. Textile and clothing production is a mainstay of some economies

What would happen to employment if brands suddenly stopped manufacturing in places with low-cost labour? This was a question put to Clare Farrell (co-founder of Extinction Rebellion) at a sustainable fashion event earlier this year where I invited her as a guest speaker. She was very straightforward in saying she had no answer for that (does anyone)?

FYI, one view put forward by Kalpona Akter (Bangladesh Centre for Worker Solidarity) in the Autumn 2019 issue of Peppermint magazine was “we want these jobs with dignity” rather than a boycott which would mean loss of jobs.

What about ethical offshore production?

I’ve found more of a big deal being made of ethical production / social justice amongst sustainable fashion brands rather than fabric manufacturers. By social justice I’m referring to things like better working conditions, family-run factories, giving local artisans a global platform for their work etc.

Whilst I’m all for the social justice side, it makes me mad that sometimes the same brands massively greenwash on the eco side. I acknowledge that no one does things perfectly but I have boycotted brands before if I’ve received a dodgy (or no) email response from them when I’ve asked about their eco marketing and credentials.

Final words on local production

From where I stand, it’s about being selective. On the environmental side, it’s a nice idea that my stuff doesn’t have to travel that far to get to me. (This might be totally the wrong answer from a carbon perspective if production efficiency outweighs the transport.).

More significantly though, because local businesses are often smaller, I feel like there is a tangible economic impact on the local / regional economy. And if I live here and I’m in a position of privilege to support this, then why wouldn’t I?! Like everything sustainability-related though, it’s a decision for each individual to make on what matters and what you can feasibly do.

Click here to read about the fabric project woven with recycled yarns where production is in the Netherlands.