It is nearly spring in the UK! As the early bulbs start to flower in the local parks, viscose and rayon challis is out in force in fabric shops. After the beginner “sew everything in cotton” stage you have probably moved on to this stuff or at least seen it for sale. On the surface it seems great – who doesn’t want a breathable fabric with lots of drape that comes in a zillion prints? And a lot cheaper than silk!

But as usual there is a flip side on the sustainability picture. There are a lot of shock horror type stories associated with viscose (and general textile) production such as the Guardian article here, so I thought it would be an idea to see where the land lies on this. Turns out the viscose fibre family is not simple – I’ve already spent hours on reading and still only come up with a high level view. But hopefully this post will give you a small intro to a big topic and give you some things to think about. Let me start with some definitions:

Viscose, modal, cupro, lyocell all belong to the family of “regenerated cellulose fibre” or “cellulosics”.

• Viscose can also be called rayon according to the US Federal Trade Commission

• The trademark name for lyocell is Tencel.

• EU legislation gives each fabric a slightly different definition depending on the processing, but ultimately the raw inputs are the same – plants (mostly trees).

Regenerated cellulose – a natural man made fibre.

Sounds contradictory but makes sense. Cellulose is natural as it is a carbohydrate within plants that gives them their stiffness and strength. But cellulose needs to be first extracted. So it is turned firstly into a pulp (known as Dissolving Wood Pulp, or DWP) and then spun into a fibre (i.e. regenerated / made made).

Viscose fabric is >91-95% cellulose. Did you know that cellulose is in almost everything? Over the past 200 years the uses for cellulose has massively increased – paper is made from cellulose, toothpaste and washing powder fillers use cellulose and so do baby wipes.

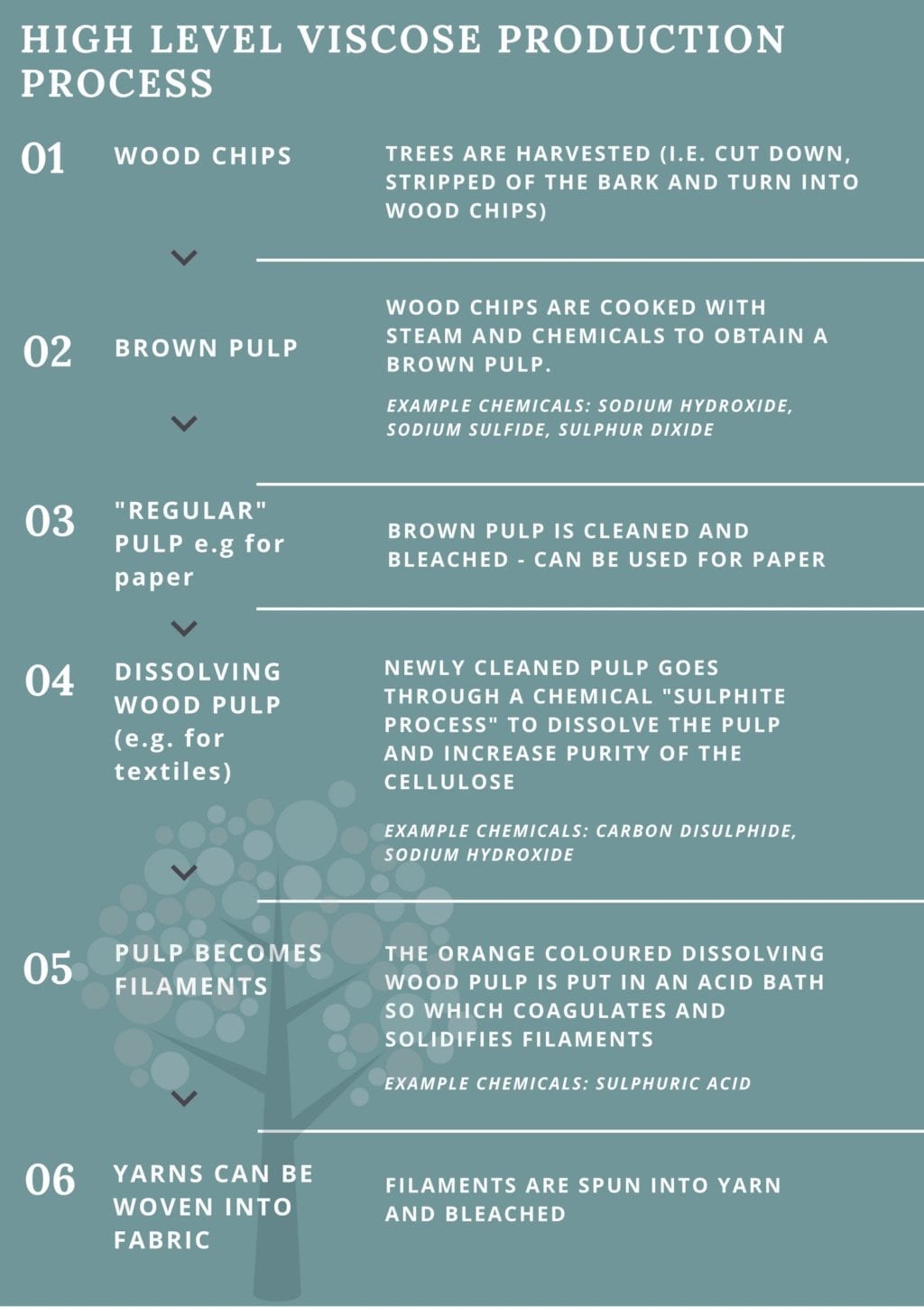

The production process at a glance.

This infographic is my interpretation of the production process. But there are variations in chemicals etc. depending on who makes it. Also I am no chemist so if any of you know better than me are please tell me if I have gone wrong!

Who makes this?

There are a limited number of viscose producers operating in limited geographies, with 5 companies collectively producing >50% of global DWP production. Whilst there are other sources of DWP, at this moment cellulose is primarily sourced from hardwood forests and plantations (source: Water Footprint Network). The company Sappi for example produces around 20% of the world’s DWP, and states on its website that it uses eucalyptus, aspen and maple trees from sustainably managed forests and plantations.

Environmental considerations with production.

1. All cellulosics – viscose, Tencel, modal, cupro – need trees.

The CanopyStyle campaign run by Canopy Planet (a not for profit organization focused on forest protection) emphasises sustainable tree sourcing, and there are some pretty depressing statistics:

- 70% of the tree is wasted in the production of cellulose.

- >150 million trees are logged each year for textile purposes. Deforestation is happening in Indonesia, Canada’s Boreal and temperate rainforests and the Amazon for cellulose production.

Whilst I believe Canopy Planet is likely to be a reputable source given their high profile I still feel uninformed on the scale of the problem. For example, I wasn’t able to find how much deforestation is attributable to viscose production. And also how much is 150 million trees? According to the Rainforest Network, forest density can vary between 50,000 to 100,000 trees per square km. This means that every year, 1500 – 3000 square km is being used for viscose. When this is compared to the general figure of 70,000 square kms of forest being lost each year from timber harvesting, agriculture and wildfire spread (source: Intactforests.org) it suggests we have better things to worry about than trees for viscose. Another thing I don’t have an answer to is why trees are still being used when it could really be any other plant (cotton linters, bamboo etc. I’ll look into bamboo another day).

Pine plantation, source: Upsplash

2. Viscose production is chemically intensive, many of which are hazardous to health. The chemical processing also results in emissions and effluents.

The consultancy Made-By has made an environmental benchmark for fibres, which is graded from A (good) to E (bad). Most of the viscoses are E, modal is D, and lyocell is B – not great is it! For reference, the criteria includes emissions, human and environmental toxicity, and land / water / energy use. I suspect this is largely due to the chemicals in use and the difficulty with disposing of them. For example, for wood pulp to be dissolved (step 4 on the infographic), the pulp needs to be treated with carbon disulphide and then dissolved by adding sodium hydroxide. You might know this as caustic soda or lye. Both are toxic chemicals and hydrogen sulphide (rotten egg gas smell) is generated as a by product. Note – there are many different ways to assess fibre sustainability and this is one of many methodologies done by many parties.

But progress is being made.

Whilst cellulosics make up only around 7% of the world’s fibre production for textiles (the majority is cotton and polyester), this is set to increase in the coming years. Fortunately, seeing that there is only a limited set players in the viscose supply chain (the USA is the largest producer of DWP and trees for DWP?) you would hope that the push for sustainable tree sourcing would not be insurmountable. Canopy Style has made headway into this after 4 years of campaigning:

• 125 brands / designers have committed to eliminating endangered forests from their sourcing.

• 11 viscose producers representing 70% market share now have endangered forest sourcing policies.

Is it enough?

Rainforest Alliance audits of supply chains using Canopy Style criteria show 25% of the entire viscose supply chain is now at “low risk” … but that means 75% that is still not low risk! Of course it is better than 0% but as with so many other environmental initiatives I would need to do a lot more reading to have a view on how much is too little too late.

—

The sewist perspective

Personally I am not a great fan of viscose despite the positive aspects (drapey, smooth, breathable, not expensive etc). The wrinkling and slippery-ness is mostly too annoying for me to deal with – but after looking into this I will be thinking triply hard as to whether I even want to buy it. Given the difficulty with fashion companies being able to unpick their full supply chain there is little hope for the average consumer finding information on where their fabric comes from. Particularly if a fabric store sells overstock which could have come from any factory. On that happy note, I’ll leave you with a picture of one of the viscoses that did the rounds in all the shops last year (which I turned into a Sew Over It kimono).

What do you think of viscose? Do you like it as a fabric? Do you have more questions than answers after reading this?

26 comments

More food for thought. I do like the drapinessential of viscose and had thought it was ok as it was a ‘natural’ product and doesn’t use all the water that cotton production uses. However I hadn’t thought through the process or really heard about all the minus points. Hmm. I think there is bad in almost all fabric production and thank goodness enlightened souls are trying to improve this. I think the answer is. ..As with everything. ..to buy consciously and make sparingly. …We all have and want too much/too many.

Oh Judith I’m so happy to hear your sentiment – I hope the subconscious messaging on this blog of buying less and using less also comes through! Yes every fibre has its goods and bads although some are less bad. I want to raise awareness of how stuff is produced so people can make their own judgments – even if I still maintain that the best fabric is the one that already exists already. In our case it’s probably the one you have already bought!

I’ve hated viscose since it first exploded onto the market (I’m 63 so I do actually remember that 🙂 ) I remember women saying, “This is a natural fabric and it’s just like silk and so inexpensive!” I thought to myself, “This is definitely NOT a natural fabric.” Then I found out it was squeezed out of wood pulp and I was surprised to discover it IS a natural fiber! I was always suspicious though and as time went by and more info (like what you discuss in this article) was released about how it was made, I realized why it never felt natural to me. Ah! Yet another tune of, “Live better with chemicals” song.

One wash and most “viscose” turns into a rag – it loses it’s body almost instantly which most sewists discover after prewashing. It’s wiggly to sew (every bit a pain as silk if not more so since it also GROWS!) and all that fuss for cheap fabric that will inevitably look horrid after a few washes? No thank you. If I’m going to go through all the steps necessary to get something on grain (stiffening, cutting singly, walking foot, hanging) I’ll go for silk any day. Silk lasts generations, it’s stable, it will stand up through more washes than you can even imagine, shrinks very little and feels fabulous against your skin.

I’ve always been nonplussed about why cheap fabric is desirable to sewists anyway! All the work we go through to construct a garment (hours and in some cases weeks!)… and we honour all time, effort, creativity with cheap materials? My feminist voice has much to say about this issue Because it is predominantly a women’s hobby – do women always feel as though they have to justify, apologize, take up as little space as possible even when it comes to their hobbies? Are women not allowed to have hobbies? Must their hobbies always be only practical in nature?

You make some interesting points there Kathleen. I must admit I didn’t think too hard about what fabric I was using until I had been sewing for quite awhile – because I didn’t understand too much about how fabrics behaved so differently in their look and feel. Same way that I didn’t think too hard about what was in my RTW when I went shopping and what that meant.

On the cheap fabrics – I’m not sure where you are located but certainly in the UK, sewing with nice fabric is an expensive hobby! If you are just starting out and don’t know whether you want to invest in it or not then it’s easy to buy cheap. Especially if you just want a couple of cushions or whatever. Also if you don’t have the means to buy expensive fabric then I guess you make do with what you have. I don’t think this should preclude you from enjoying the sewing hobby – though you could say then that better quality second hand fabric would be preferable from a sustainability perspective.

This was a great read. I really like viscose but have always felt that the process must be chemical intensive. It’s really hard to know which substrates are actually the worst – it basically feels like they’re all bad so we may as well just choose the fabric that is most appropriate and that we will want to wear year in year out. And not buy too much of course!

In regards to the tree wastage, I am curious if this is a actually big problem or not. Each year we grow crops in our vege garden and probably 90% of the plant is wasted in harvesting (as we do not have green thumbs!). It still feels better to have some plants growing there rather than none. Surely the carbon captured during the life of those trees is a positive thing, providing they are continually replaced? Very interesting – thank you!

Hi Naomi! Thank you for your comment and kind words. At the end of the day every fibre comes with its own problems though some are worse than others – and I am in complete agreement that we just shouldn’t buy too much. Ultimately in my mind the best fibre is the one that already exists so the more we can thrift etc. the better (I’m totally guilty of not doing this enough).

On the carbon sinks – Forestry is not a topic I’ve looked into much, from what I have read, there are some arguments for replacement forests that they can be better than old growth forests in terms of carbon absorbing properties … but cutting down the old growth forests releases a lot of carbon that is already stored (and old growth has biodiversity etc which is worth caring for).

On tree and plant wastage – I think stuff like bark can be used in briquettes, fuel. I couldn’t find much on the 70% wastage but in the end I decided that it probably wasn’t worth worrying about too much given the low percentage of trees used for textiles. Sorry I can’t offer any more insight into this year! I think its great that you can have a veggie garden. Even if there is a lot wasted it still gave you happiness. In my area the council picks up garden waste and turns it into compost. Maybe you could see if there is a similar thing or home compost yourself if you have the space?

This is all very interesting info. Although sometimes I don’t want to know too much because then it makes me have to consider the impact of my actions! I don’t use silk because I consider it inhumane, so I do like viscose as an alternative – although I agree with the other commenter about its durability. I think as a knit it can be very durable, easy to work with and has a lovely drape. In woven I love it when blended with linen. I seem to be following a similar trajectory to a lot of ‘new’ sewists – year 1 – make a bunch of pretty Cotton dresses you never wear, year 2 – make all the latest indie patterns that come out and wear about half, year 3 – make a conscious effort to only make what you know you like to wear and year 4 – have a wardrobe full of clothes you like and then start to consider f you should be buying/making something new every weekend when you can no longer find enough days to wear what you have and you never used to spend this much money on rtw clothes!

Great post – knowledge means we can make better choices. Thanks for all your research.

Hi Ros, thanks for reading! It is easy to be depressed by how much damage humans are doing to the environment generally when you start to unpick at it. So I am really trying to be balanced and non judgmental about the sewing hobby, and as you say, give people some ideas to make better choices. And yes, I am coming into this as someone who has been sewing for a few years and needed to take a break when I had too much stuff. I love your trajectory that you described, it sounds VERY familiar indeed!! Regardless of the fibre you are using, if you are caring for and loving the things you have, then that is already a win in my book. Thanks again for the comment.

Haha Ros, you’ve absolutely nailed it with the new sewist trajectory! I’m somewhere between years 2/3!

Oh, Rayon! Me too, love the drape, hate the wrinkles, and scratch my head as it behaves unpredictably after a wash or two.

Thanks for the info, Kate! Viscose has its place, and I for one will choose it over polyester. There surely are pros and cons for every fibre and fabric :/

Hi Sil! Thanks for reading and your kind words as usual. I can’t say that my viscose garments are my favourite to wash either (and so much ironing afterwards) but it is there and demand as a fibre is growing. Right now I am looking at my wardrobe and my stash and not buying anything!

Omg how you opened my eyes with this… I always heard and thought that viscose was the way to go. Even when I work for fashion brands I suggest viscose as an alternative to silk (cheaper) and to poly (nicer, more conscious) not knowing or maybe shut my eyes to the downsides? One reason is because it’s so hard to find any good information at all on these topics… Therefore I thank you for writing this. I definitely got more questions after reading this though. 🙂

I loved viscose for the drape and softness and also as a knit as Ros said. I will think twice before I buy it again though… And the washing and handling of viscose garments were always a weird experience. I love your point of thrifting! That’s how I source most of my fabric and when making toiles I always try to use worn out sheets. Refashioning etc.

One reason to not start a fashion brand of my own has always been for this reason. I don’t want to be a part of the mass destruction so to say… Instead I’m making sewing patterns and try to educate my community to source fabrics consciously. We all do what we can and sometimes it feels hopeless to be sewing… But I do believe we make a difference by buying less RTW and make an active choice when it comes to fabric. Like #makeyourstash for example. Just perfect.

Hi Josefine, very happy to hear that you found this useful. I found there is a lot of conflicting information and greenwashing out there. Really had to read a lot of stuff before finding things that were detailed and reliable and I still don’t have all the answers. I don’t have a lot of pure viscose but I noticed some of my knitwear in RTW these days is a viscose blend and it as you say very soft. In fabric shops I never find the kind of knit fabrics I like that mirror the ones in RTW shops, maybe I am looking in the wrong places. Actually I don’t have a problem with buying RTW if it is from a sustainable brand or you are like my boyfriend who can make a pair of trousers last for 10 years. Sewing has become more popular which is a great thing and an outlet for creativity, but if you are buying loads of fabric and making a lot of things then I don’t see too much of a difference from buying a lot of clothes (except of course the garment worker – but that is just one part of the equation).

As for toiles, I rarely toile because I don’t want to buy calico, but the used sheets is a good idea if I ever need to! Have seen plenty of those in the thrift shops – that is a good tip. Thank you for reading!

I recently bought some bamboo silk (aka bamboo cellulose viscose) I asked the fabric store whether it was a closed loop chemical process i.e chemicals used again, and they actually checked for me, it was – I bought. I personally love the feel of viscose and I even like sewing with it. I think my bugbear was the man-made element not necessarily the cellulose source. Although excellent food for thought – 70% of the tree wasted in cellulose production. That’s awful!

Hi there, I tried to find out a bit more about the tree wastage figure but couldn’t find anything useful enough to put into the post. That is great that the fabric store seemed to know where their fabric was from and checked for you. Assume they had bought it from a textile manufacturer rather than overstock I’m interested in your comment that they said it was closed loop – from what I understand the chemicals from the bleaching process can’t be recovered. I do have bamboo on my list of stuff to look at though!

Viscose definitely has its place in the garment industry and it seems to only increase in popularity. I like the blends (in knitwear particularly) that is in RTW stores but I’ve not been able to find equivalent fabric in fabric stores (I’m referring to the stuff that you would see in say a RTW cardigan, not a standard jersey) – if you have any ideas please do let me know! Thanks for reading x

This is very enlightening Kate and I do find your blog to be so informative and thought provoking. I had thought I didn’t really buy ‘new’ viscose as I go for vintage fabrics if I’m buying viscose at all. But then I realised I have used a lot of new cotton viscose mix jersey for the leggings and stretchy tops I wear as a base layer because of the soft feel quality. I think the more I learn about fabric production and the circumstances in which it’s made and ultimately discarded is having an effect on whether I want to ever buy new fabric at all. I’m sewing my stash and up cycling what I have as usual but if I ever feel the need to buy a bit of yardage it’s going to be from someone else’s destash or used. I think we over consume generally, I think back to when I was in my twenties and I had a few clothes that I wore on heavy rotation, nothing went unworn. On the properties of viscose itself, I do like it because it accepts dye well and if I’ve found a garish vintage print in the past I’ve over dyed it and it mutes it to a nice effect. It’s a slippery sucker though but gathers and drapes well as others have and I do like how soft it is. I think the key is to buy used if you have to buy at all. It would be cool to see a destash website where folk could buy and sell fabric that’s already been produced. I don’t know how well that will go down with those that like new and latest fabrics but there is a growing mindset out there who aren’t comfortable with the mass consumption of new goods. You are doing a great thing in providing information to the sewing community on these issues and hopefully the seeds are planted and changes will come X

WordPress has gobbled up my comment!! In a nutshell Kate I wanted to say that you’re doing a great job of providing this information to fabric consumers (because that is what we are, mass consumers) and hopefully those seeds will effect change in attitude to making. We’re just as responsible as folk who are in an endless cycle of buying fast fashion. We need to slow down, and buy used if at all. Use what we have is best but there’s plenty of ways to get hands on used fabrics to make with. My initial comment about the properties of viscose was, I like to overdye vintage pieces I find, it accepts dyes well and feels soft to the touch. I have made all my base layer items like leggings and stretchy tops in the past from a cotton viscose mix so will be rethinking if I ever need to replace.

Hi Josie, thanks for your comments and reading. Another commenter outlined the sewing learning cycle pretty well I thought – year 1 learning and everything from woven cotton, year 2 expanding the fabrics and making everything, and after that slowing down a bit. Its easy to get sucked into the rabbit hole that is sewing without realising that the endless buying cycle of fabric isn’t that different from fast fashion as you point out. I have 2 packets of dye which are waiting to be used – I’m hopeful they will revive a pair of faded black trousers and a faded indigo linen dress. Alas neither are in such a poor condition that they are unwearable so its taking me awhile to get round to it. I have been on a buying hiatus for near on 3 months now and it definitely feels good to lose the guilt of never having time to make all the stuff I would want to buy. Now to attack the stash in a controlled manner…

As ever I always love hearing from you and I love your ethos, your creativity and totally unique look. Thanks for reading and commenting, and of course sew on! X

This was so interesting to read! I was happy to see your challenge over on Instagram to use our stash and make something with it. I was big on fabric shopping before and my stash grew a lot in the last two years, but in last 6-8 months I buy less. And when I do buy I go for natural fabrics (I feel good in them and I think they are better than poly fabrics for me and the environment). I was always aware of natural fabrics not being ‘clean’ but now I love reading articles like this to learn more about them. It makes me sad when I know that the fabric that bring me joy does not do that to environment or possibly (or probably?) to people involved in the production process. I love viscose (although it drives me mad with all the wrinkles) but I love wearing it. I do hope things will change for better, not just with viscose, but with all fibre production and more importantly the whole fashion industry. That industry in the big player that can implement changes faster but how do we get there?

Would love to read more of these articles if you plan to make them in the future, so I followed the blog 🙂

Hi there! Nice to meet you – its funny isn’t it how we are always taught to believe that natural is better, which isn’t always the case. Having said that with everything there is a good and bad. I think we each have to find a balance with things that bring us joy vs what we use, and educating yourself is a good step. The fashion industry is changing albeit slowly, but because sustainability is “on trend” you have to work out what is greenwashing and marketing, compared to what will actually do good. I believe that change comes at all levels. If consumers don’t demand then companies don’t do anything. But similarly without being given any choice, its hard for an individual consumer to make a difference.

I do plan on writing more of these articles. But I am sure you will appreciate it takes me a lot of time to do the research and find reputable sources so I can try and present accurate information – each month I’ll aiming to do at least one. Thanks for following along, and of course joining in with #makeyourstash! Kate x

I know it takes time and appreciate it! I just wanted to support with a comment and let you know I love reading them! I know that single customer cannot make a change so I do hope there will be more of us asking questions

I am more concerned with the impact of the chemical processing in rayon production than the tree use. There is a new book written about it that I am tempted to read, but honestly, I’m too afraid to. If you enjoy sewing and wearing drapey prints, rayon is usually the only option available outside of polyester. So if I really love it, I turn a blind eye and choose the lesser evil.

I just discovered your blog and am really enjoying it. I really appreciate the research you’ve been doing and reporting to us. And basically I love your message that really the only good solution is to use less stuff.

I got here via a link from another blog, on the topic of viscose being “bad” for sustainability. To me that implies less sustainable than something else. You’ve mentioned silk as what viscose is in many cases replacing, so I’d love to see a future post about silk. And possibly also cotton. Just glancing at the Higg and Made-By benchmarks that you’ve linked to (in the lyocell post), it doesn’t look like silk is any better than viscose, but as you mention, those numbers by themselves don’t say what the measure is based on.

In general I wonder if you recommend natural fibres over synthetic, or vice versa, from an environmental perspective. Natural feels very virtuous to me, but cotton, wool, and silk all come out looking pretty bad on the Higg scale.

Hi there, thanks for reading and happy you found my blog! There is no one single standard to measure sustainability of fibres. Some look at production, some look at the whole lifecycle (including consumer use and post consumer) – the ones I have cited are the two of the more common ones used by brands. I do have plans to write about other fibres in future, thanks for telling me what you would like to see.

In terms of natural vs synthetic. Its quite a debate! On of the main arguments pro natural is that they biodegrade (break down), whereas synthetic photo degrades (breaks up). However, a recent documentary which dug up a 1980s landfill found cotton clothing in near perfect condition! So the argument might be valid in say a thousand years (arbitrary number)… Personally I don’t buy polyester for everyday clothing because I just don’t like the feel of it – but I still wear the polyester I already own. On the flip side, having an element of spandex is obviously useful in say jersey. And synthetic is really good for outerwear (windbreakers etc). I try and look for recycled polyester but its not that readily available, or very highly priced. But it is up to you really – there is no one size fits all correct answer for me.

I never favoured polyester nor viscose in RTW only by the feel of wearing those fabrics (they make me sweat more than usual and then make me feel gross). And at that time I didn’t even know their definitions. Now that I do, I’m convinced my gut feeling was right and I will continue to try and avoid these kind of fabrics and stick to my preferred choice: cotton (and occasionally linen).

Thank you for your explanation!

Hi Angelic, thanks for your comment. Viscose and lyocell make me feel gross too, and when they come out of the washing machine in this wrinkly mess… ugh. I’ll take real silk over this artificial stuff any day! Sadly it’s a bit more involved to maintain. My favourite fibre is linen. Which reminds me I need to write a blog post about cotton, organic cotton, linen, etc. Sew much writing (and sewing), sew little time!