I love speaking to people that are doing fantastic things in sustainable fashion. Annemieke Koster owns her own weaving mill Enschede Textielstad in the Netherlands, with makes fabric from recycled yarns. Want to learn about the recycled cloth process? Read on for an insiders view!

What’s the story of Enschede Textielstad?

I started my company 5 years ago. I was working as an online marketer in an advertising agency when the Rana Plaza disaster happened. All the experts were saying that we should buy expensive brands, made in Italy etc, and really focus on working conditions. But we know that price doesn’t always mean quality. And also working conditions are the last step in the chain of garment production. When I started to look into this more I initially intended to do an awareness-raising exercise, but then decided to be more active. I had never been in a weaving mill before, but my home town has a history of weaving. After speaking to a lot of designers and companies about sustainability – what they were missing, how they could improve – I decided to weave cloth in my hometown with as much sustainable content as possible.

What does sustainability mean to you?

A balance of ethics, aesthetics and functionality.

A conscious decision based on different parameters.

For example, if I was asked to make a fabric for a bench in a public space, I would advise against using post-consumer denim because it is less durable. Production waste would probably be a better choice. In fibre terms perhaps it is less sustainable, but to reupholster once every 5yrs instead of every year to me is more sustainable. Also – you can make really good recycled fabrics but if they are not appealing then there is no point!

What kind of fabrics do you weave?

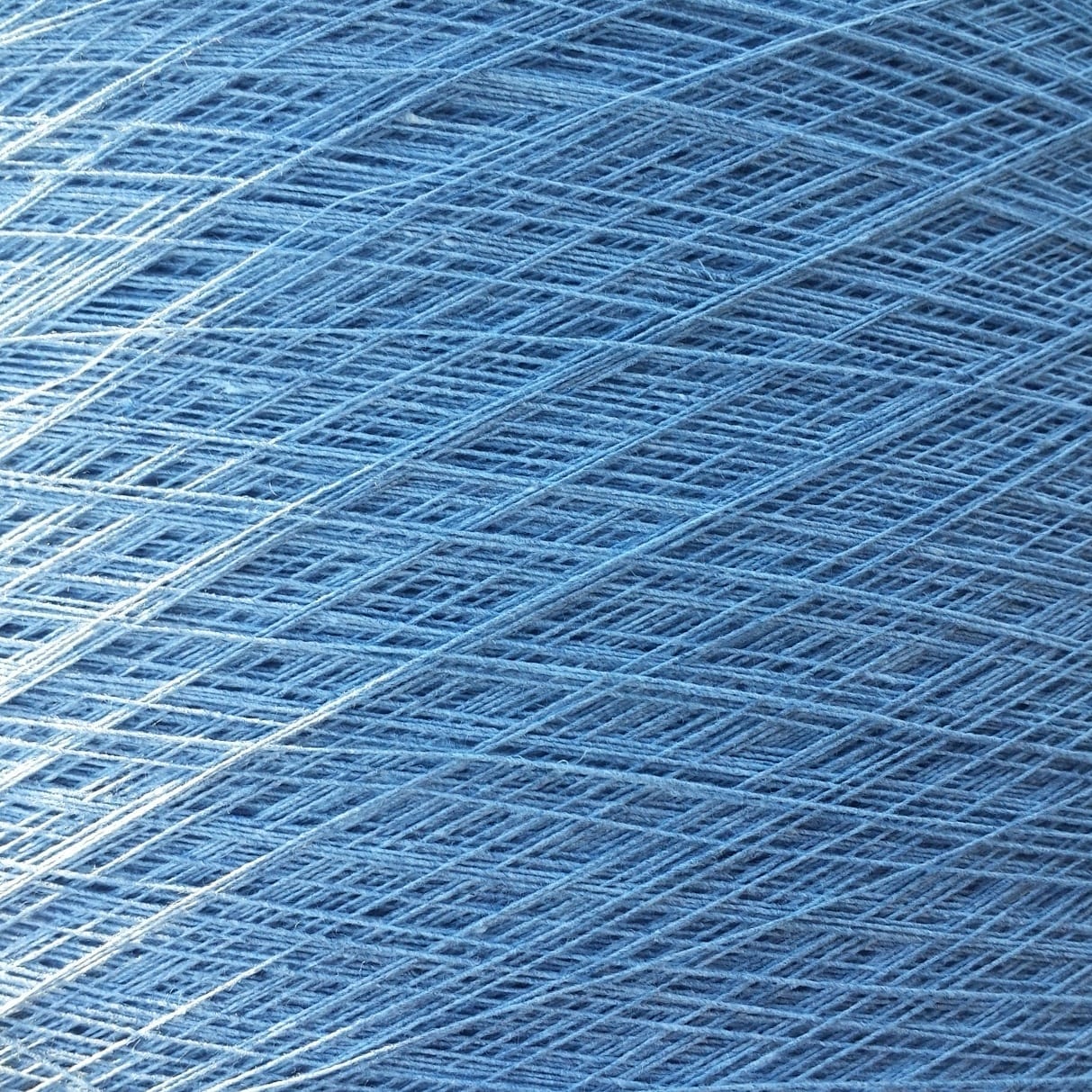

I started with fashion fabrics. First I developed a chambray which was 78% recycled cotton, then decided to try thicker upholstery fabrics. My specialty is using recycled yarns. Production is on demand and I keep limited stock. My minimum order is 1m (used for things like fashion shows) and commercial orders can be a couple of thousand metres.

In most of my fashion

Where do your yarns come from?

Local sourced with European yarn is one of my basic values. There is a textile collector and recycler 12 km from the factory that also spins yarns. There is another company in Enschede which sews garments. I don’t have a standard weaving mill or a standard customer/supplier relationship. I prefer to collaborate and encourage all my customers to produce and sell locally rather than for example have fabrics produced in Europe, then garments sewn in Asia and then sold in the US.

But not everything can be found in one area so I do have suppliers in Belgium, Spain, France, Italy. There is so much textile waste globally, sometimes it is better to consolidate the sorting rather than doing small production runs using just Dutch waste. I have taken part in different research projects on using hemp and flax in the Netherlands in a closed loop system. It is promising, but not on an industrial scale yet.

Lets talk about waste….

There are different types of waste:

Post industrial : for example from garment making workshops after the pattern pieces are cut. Fabric is expensive so cutting is carefully planned, but there will still be 5-10% waste, and more if there is a distinct pattern. Spinners and weavers have waste as well. I collaborate with spinners that assemble production waste to sort by composition and colour.- Post consumer: what you and I don’t want anymore. The clothes are sorted by composition, thickness, woven or knitted (just to name some criteria) – then shredded.

- Used workwear: i.e. companies with uniforms. I have worked with a supermarket chain which had a lot of acrylic sweaters. In this

instance the composition was known which makes it easier to ensure we havehigh quality yarns.

And how is waste recycled?

- Chemical recycling – dissolving clothes – this is promising but not yet on an industrial scale. There is a company in Enschede who are investigating this and they are able to separate cotton and polyester fibres. But it is harder if there is a blend of many fibres, or the structure of the garments is quite different.

- Mechanical recycling – shredding clothes. Using jeans as an example, the highest grade of jeans are sold at thrift shops. The low grade ones are shredded. The technology is so advanced that bales of jeans can go into a machine that removes all the zips and metal parts. But some spinning mills don’t want the risk of small pieces getting into their machines, so sometimes the jeans are cut off at the legs. Then a machine with small knives will shred the fabric into small strips. This is carded, laid in the same direction and eventually mixed with virgin fibre

What about colouring?

There is no need for me to colour fabric. Weavers and spinners don’t dye much – if they do, it would be recycled polyester that is dyed with a low impact dye. There is so much waste that it is easy for companies to sort in Pantone colours and create a whole colour range.

*For a virtual tour around the factory and weaving in action, check out this video. *

Why are recycled fibre garments in shops often not 100% recycled?

Theoretically in weaving, the warp (fibres going lengthwise on the grain) and weft (fibres going across) can both be made using recycled yarn, but quality reduces so much it will not make a product that lasts. The warp endures a lot of tension in production, so it is difficult to have a high percentage of recycled cotton in the warp. On a large scale, many companies opt for recycled polyester or virgin cotton in the warp.

You are more likely to find 100% recycled in knitwear as you can ply the yarn to make it thicker.

Let’s talk about the broader context…

What do you think slows brands down from adopting more sustainably produced materials?

It is difficult to shift to a new business model. The linear system of production means there are margins taken by each party at every stage which doesn’t work with sustainability. Many companies try to improve different parts along the chain, e.g. working conditions. But as long as it continues to be more cost efficient to ship a whole container of garments rather than just buying what you need, then the situation will not change.

How do we reconcile the need to produce more sustainably with the need to buy less?

Quality over quantity, and more added value to products. I strongly believe that the way we consume needs to change. You can buy trousers for £50, £10, £200. If you take into account all the production steps, from growing the cotton to the garment being sewn, £200 could be cheap even if it expensive compared to the others. At least if you make your own clothes you know some of what goes into it, including cutting and sewing.

Do you think there is a cultural problem?

When I teach sometimes as a guest lecturer, a lot of students tell me they don’t have a big budget but want to be more sustainable. For

If you focus on the basics you actually wear a lot, you would be surprised by how little you need. Also if you know the maker (mother, grandmother), you are less inclined to throw it away.

Maybe there is a gender bias as well. I saw in the media once there was a TV show host who claimed to wear the same suit for a year and no one said anything, but his female co-host wore the same blouse 2 days in a row and people online went crazy.

What’s next Annemieke?

The launch of my webshop is the next thing, to make my materials accessible to retail consumers. 1m is the minimum.

Thanks to Annemieke for her time and providing the overview of recycled textiles from a weaver’s perspective. If you’d like to keep up with Enschede Textielstad and watch out for the launch of the webshop you can check them out on Instagram. All photos are courtesy of Enschede Textielstad.

PIN FOR LATER:

3 comments

I, for one, am really excited about this!

Happy to hear it! The possibility of being able to sew with fabric made from recycled yarns really seems like a novelty!

This is an eye-opener! Thank you Kate and Annemieke! It is great that companies are joining the movement and hopefully forming a whole blooming industry surround sustainability itself.