Ever thought much about what’s behind the amount of money you pay for your fabric? The questioning around how a could t-shirt could possibly cost £3 at a low priced fashion store is pretty common in the public domain. As a sewist I prefer buying fabric. But I don’t see that buying fabric as being all that different from buying any other retail product such as clothing. At a simplistic level, if we work backwards from the final price, we need to consider retail mark up and profit for wholesale before reaching the cost of production.

How is fabric priced?

There are a lot of articles and podcasts on the internet about how to price manufactured products. Here are my observations so far taken from various sources:

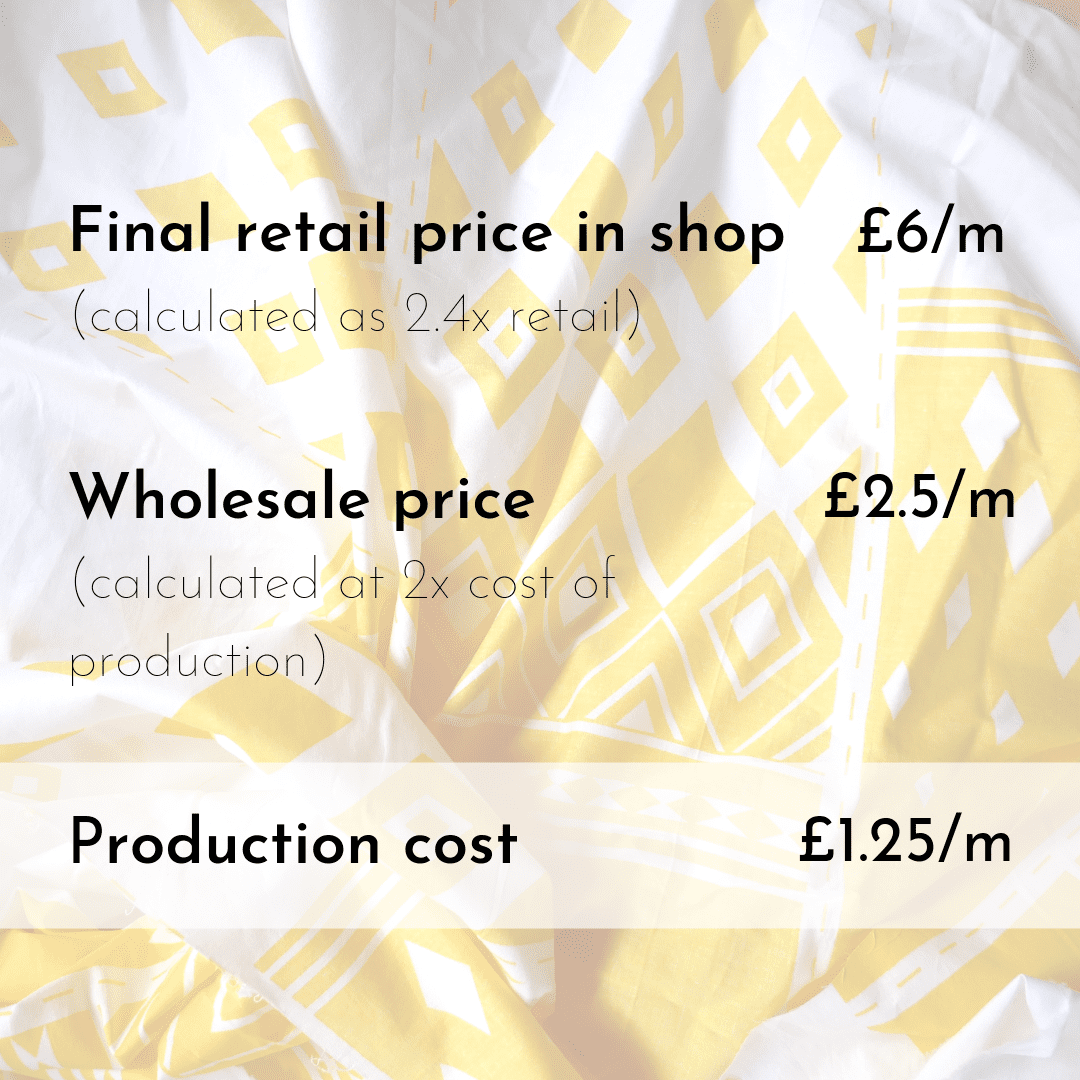

- Mimi G’s Business Shet has a podcast episode on How To Price. Her guidelines are that wholesale pricing is 2x cost of production (this includes all costs such as your webshop and accounting fees etc). And retail is 2x wholesale cost.

- The Business of Fashion book (pictured above, part of the Fashionary series of books) suggests wholesale should be 2.8x of cost of production, with retail at 2.8x wholesale.

- Annie over at Village Haberdashery (a bricks and mortar fabric and craft store in London) revealed on Instagram that she typically uses 2.4x over wholesale price. The 2.4x factors in VAT (sales tax), which in the UK is 20%. So if you spend £20 on fabric, £2 of that immediately goes to the tax man.

FYI – you can see Annie’s pricing post here on Instagram as part of her Friday business chat posts. I know a lot of people (including myself) appreciate her honesty on how her business works and gaining some understanding of what goes on behind the scenes!

Let’s now apply this a metre of inexpensive cotton I bought some time ago and still haven’t cut into, 6yrs later…

How is that interesting? Is the production cost too high or low?

There is no right answer here and honestly, I don’t know – but my gut tells ms that £1.25/m seems pretty damn low when I consider what I could make from 1m. There must be some kind of math to work out costing but alas I’m not in the industry and I’m not an academic.

Because what’s in the cost of production? There are so many different parties in the supply chain that get need to get paid. Production cost includes materials, labour, general admin, research and development as well as processing. For natural fibre processing, basic steps include needing to:

- Grow and harvest a plant or shear the sheep for example

- Turn the raw fibre into a usable one (cleaning processes etc.)

- Spin the fibre into a yarn

- Weave the yarn

- Colour the fabric

- Print on the fabric

Like the rest of fashion (and farming! or anything manufacturing), I suspect that fabric as a retail product is a volume game.

What about expensive designer fabric?

At the other end of the spectrum, you will have something like a Liberty tana lawn which retails for £22.50/m. This is probably the most expensive cotton lawn I’ve seen, but undoubtedly the quality is amazing. By amazing I mean that I have washed my Liberty lawn trousers every 1-2 weeks every week for 3 years. Whilst it’s a bit thin in places, it hasn’t ever ripped and there’s no noticeable pilling or colour fade. But for Liberty I suspect you are paying a lot for design and marketing in addition to the cost of premium cotton fibres.

What to make of this kind of math?

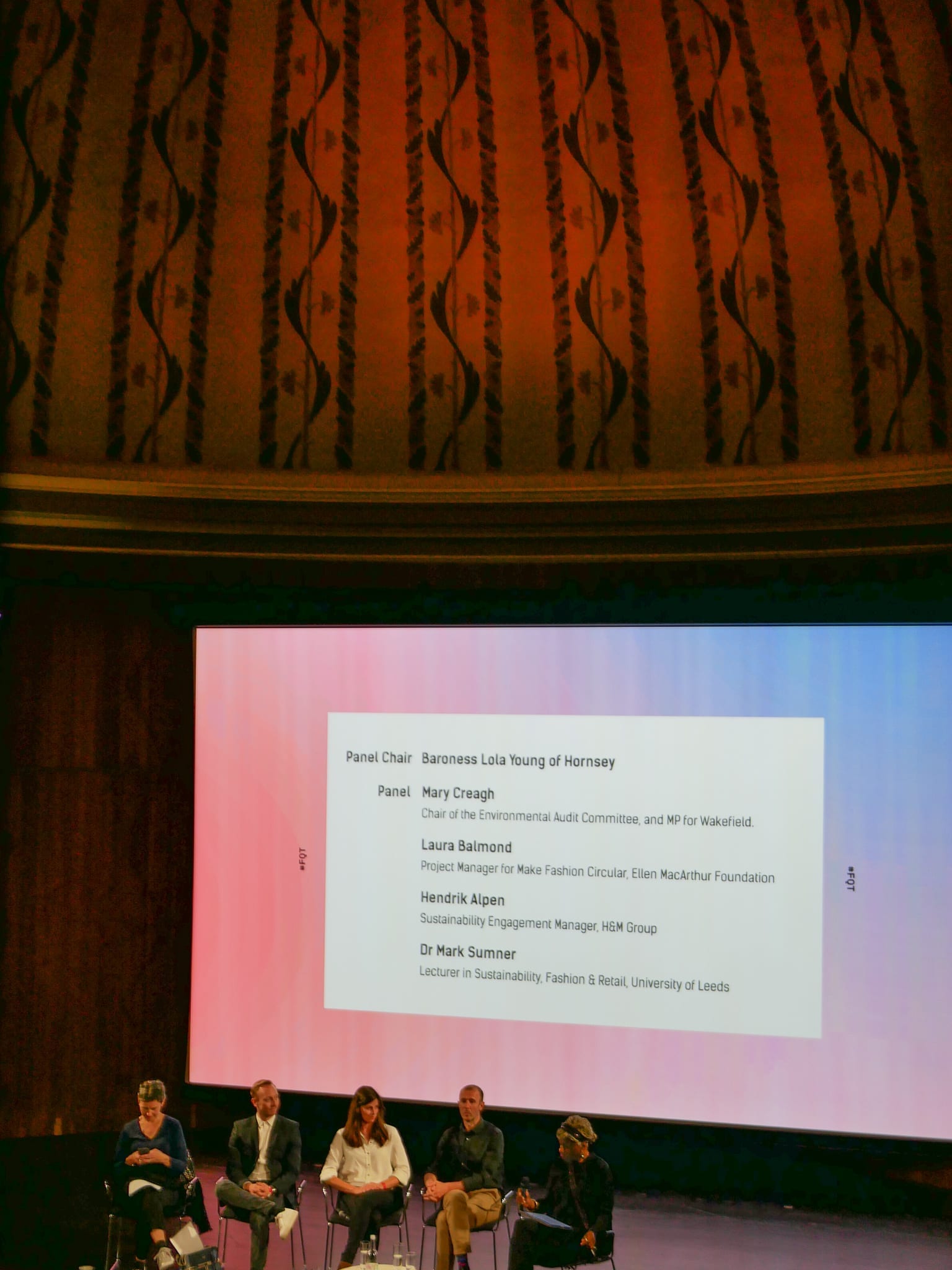

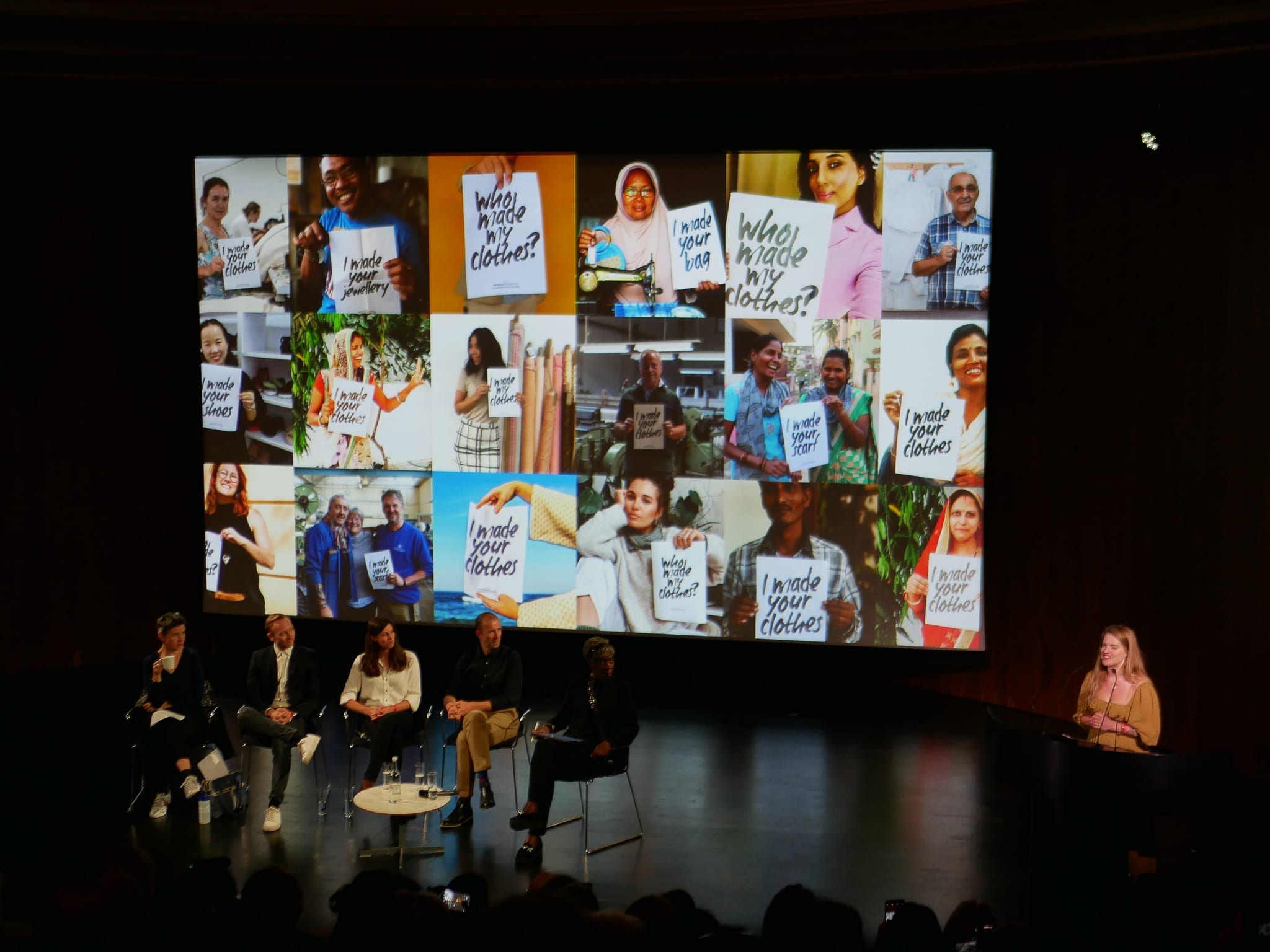

I guess this is just a reminder that for fabric there are costs to consider and a lot of people involved in the supply chain, even when there is no garment worker involved. We all know that fashion production (including fabric) is largely outsourced to India, China, Bangladesh, Vietnam, Indonesia, Cambodia etc. because of the cost. And what we often see in the media is a garment worker in the headlines (and sometimes a cotton farmer).

But at what indirect/hidden cost? There are plenty of unpleasant stories about what happens in factories in places that don’t have the same health and safety standards that we do. Not to mention the environmental issues in places where standards are not enforced (textile factory effluent into rivers is an obvious one, as profiled in documentaries such as River Blue or The True Cost).

Would you pay more if you knew what you were paying for?

The idea of value is so relative and individual. Are you buying just a bit of cloth or a sewing pattern because it looks nice? Or are you buying a story of a brand? Or because you are supporting someone’s small business? For me, it’s more about supporting somebody’s small business. Fabric shops and indie pattern brands are often individuals like you and me trying to make a living. I want them to be there and thrive!

Looking at pure product alone I think it’s hard to justify higher costs when there is a lack of transparency on what you pay for. This isn’t just fabric – this also applies to everyday goods like food, household goods, furniture etc. I read somewhere once that the point of having a £50 barbeque and a £1000 one next to each for sale is to sell the £300 one. So consumers feel like they are buying better than the cheapest and nastiest, but not spending silly amounts of money on an unnecessary luxury barbeque. Then again you could say it is all just relative because there is no other information besides comparable products!

What do you think of pricing math? What do you do to determine how much you’ll pay for fabric? If you have any insight into pricing and costing I’d love to hear it!

PIN FOR LATER: